Table of Contents

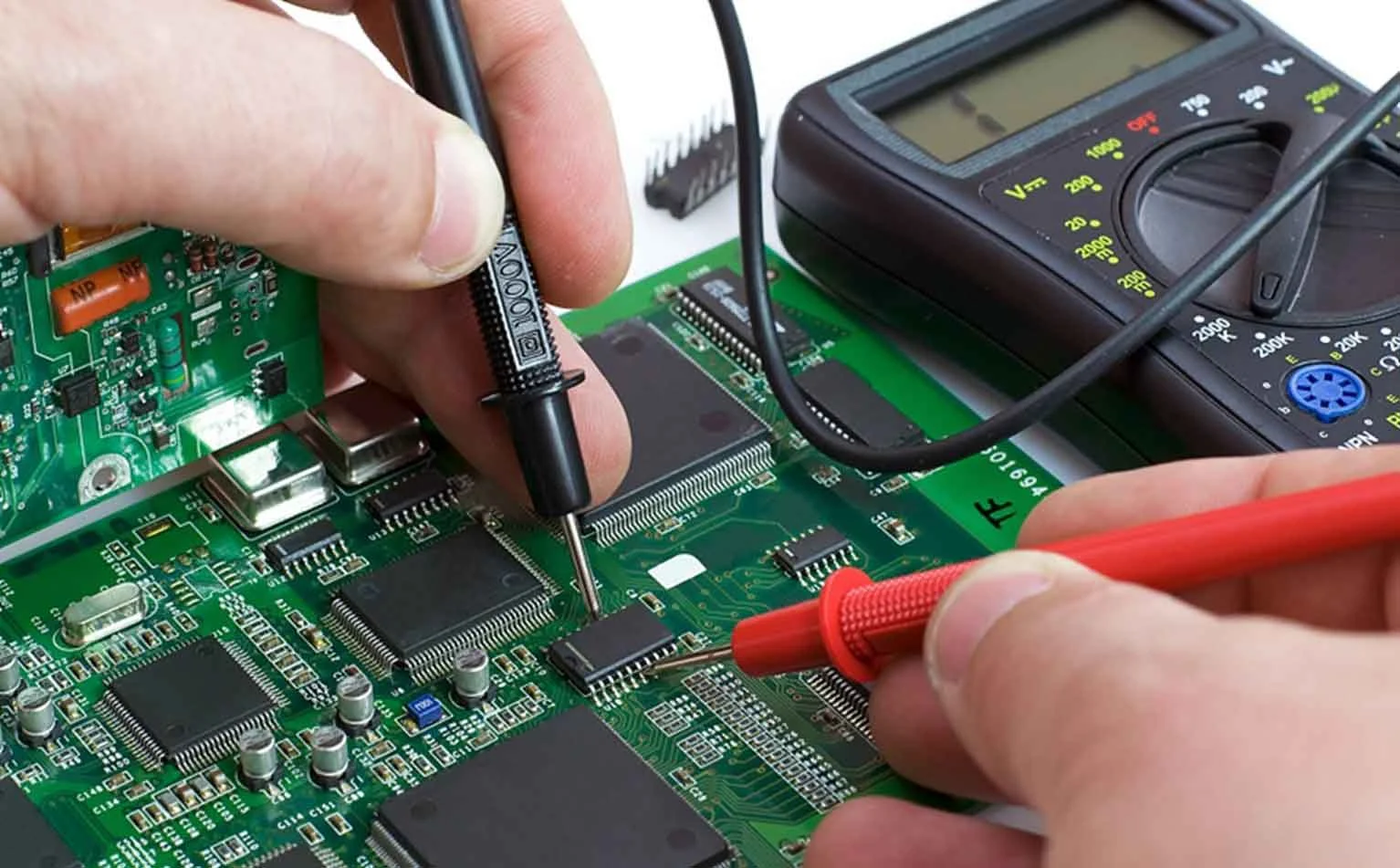

In the fast-paced world of electronics development, turning a concept into a functional product requires speed, accuracy, and expert craftsmanship. One of the most critical steps in this journey is prototype PCB assembly—the process of building a working version of a printed circuit board (PCB) to test and validate a design before mass production.

Choosing a reliable prototype PCB assembly service can significantly influence your product’s success. Whether you’re a startup bringing a new gadget to life or an established company launching your next innovation, partnering with the right assembly service is vital.

In this article, we’ll explore the top benefits of using a dependable prototype PCB assembly China and why it’s a smart move for your business.

What Is Prototype PCB Assembly?

Prototype PCB assembly services refers to the quick and precise fabrication and assembly of small quantities of circuit boards, usually used to evaluate a new design. These prototypes are built to test functionality, identify flaws, and ensure that everything works before moving to full-scale production.

Unlike high-volume manufacturing, prototyping focuses on agility and flexibility, allowing engineers to make changes and iterate rapidly.

1. Faster Time-to-Market

In today’s competitive environment, being first to market can be a game-changer. A professional prototype PCB assembly service accelerates the design-validation process by delivering quick-turn prototypes. These services specialize in fast lead times—sometimes as short as 24 to 48 hours.

With faster prototyping, you can:

-

Validate design concepts sooner

-

Identify issues early in the development cycle

-

Make necessary design improvements quickly

-

Shorten the overall product development timeline

A reliable service helps you go from idea to working product faster, giving you a competitive edge.

2. High-Quality Assembly Standards

Reputable PCB assembly providers follow strict quality standards, such as IPC-A-610, ISO certifications, or even RoHS compliance. This ensures your prototype is manufactured with precision, reducing the chances of defects or rework.

Quality control processes like:

-

X-ray inspection

-

Automated optical inspection (AOI)

-

Functional testing

…help catch even the smallest errors before they impact your product.

High-quality prototypes lead to smoother mass production, fewer recalls, and better product performance.

3. Expert Engineering Support

Designing a PCB is complex. You need to consider electrical performance, signal integrity, thermal management, and component placement. A reliable prototype PCB assembly service doesn’t just assemble boards—they often provide DFM (Design for Manufacturability) and DFT (Design for Testability) feedback.

With expert guidance, you can:

-

Optimize your design before committing to production

-

Avoid common pitfalls in layout and component selection

-

Improve your product’s reliability and cost-effectiveness

This engineering support can be crucial for startups or small design teams with limited in-house experience.

4. Cost-Efficiency in the Long Run

Although prototyping may seem like an added expense, it can save you thousands—or even millions—in the long run. Catching design flaws early in the development process prevents costly mistakes later during mass production.

A prototype PCB assembly service helps by:

-

Reducing expensive rework and redesigns

-

Eliminating trial-and-error in full-scale manufacturing

-

Allowing for efficient component sourcing and planning

Ultimately, the investment in a reliable prototype service pays for itself through fewer delays and better product quality.

5. Seamless Transition to Production

The best prototype assembly companies often offer full turnkey solutions—everything from prototype to high-volume production. This continuity minimizes risks during the scale-up phase. Your production partner already knows your product, understands your requirements, and can adapt quickly.

Benefits of using the same partner include:

-

Smooth handoff from prototype to production

-

Easier integration of design improvements

-

Consistent manufacturing quality

-

Simplified vendor management

With one partner handling everything, you save time, reduce communication issues, and avoid errors.

6. Access to Latest Technologies and Equipment

Leading prototype PCB assembly companies invest in the latest equipment and software. This includes:

-

Surface Mount Technology (SMT) pick-and-place machines

-

Reflow and wave soldering equipment

-

Advanced inspection tools

-

CAD and CAM software for design optimization

These tools ensure that your prototype is built using cutting-edge techniques, giving you a more accurate representation of your final product.

Additionally, they’re often experienced in working with advanced components, such as BGAs, QFNs, and ultra-fine-pitch ICs.

7. Flexibility in Customization

Prototyping is all about experimenting and refining your design. A reliable assembly service offers flexibility in:

-

PCB layer count and material choices

-

Component selection and sourcing

-

Mixed technology (SMT and through-hole) assembly

-

Hand soldering or automated assembly

This flexibility is invaluable when you’re testing new concepts or trying out different iterations of your design.

8. Streamlined Component Sourcing

Sourcing components can be a headache, especially with current supply chain challenges. A professional prototype PCB assembly provider often offers turnkey assembly, where they handle the sourcing and procurement of components.

This helps you:

-

Avoid sourcing errors

-

Prevent counterfeit components

-

Get real-time stock updates

-

Maintain bill-of-materials (BOM) consistency

Working with a vendor who has established supplier relationships ensures that your prototype uses high-quality, authentic components.

9. Confidentiality and IP Protection

When you’re developing an innovative product, protecting your intellectual property (IP) is critical. Reputable PCB assembly services follow strict confidentiality agreements and internal security protocols to safeguard your designs and data.

Choose a provider that:

-

Signs NDAs willingly

-

Uses secure file transfer systems

-

Limits access to your files internally

Knowing your IP is protected gives you peace of mind during the prototyping stage.

Final Thoughts

Choosing a reliable prototype PCB assembly service is more than just outsourcing a task—it’s a strategic decision that can shape the success of your entire product. From speed and quality to expert advice and long-term savings, the right partner becomes an extension of your team.

Whether you’re an entrepreneur building a new IoT device or an engineer refining a complex control system, a trusted assembly service will guide your product from concept to reality with efficiency, precision, and confidence.

Need help selecting a reliable PCB prototype service? I can help you draft a checklist or even compare a few top vendors