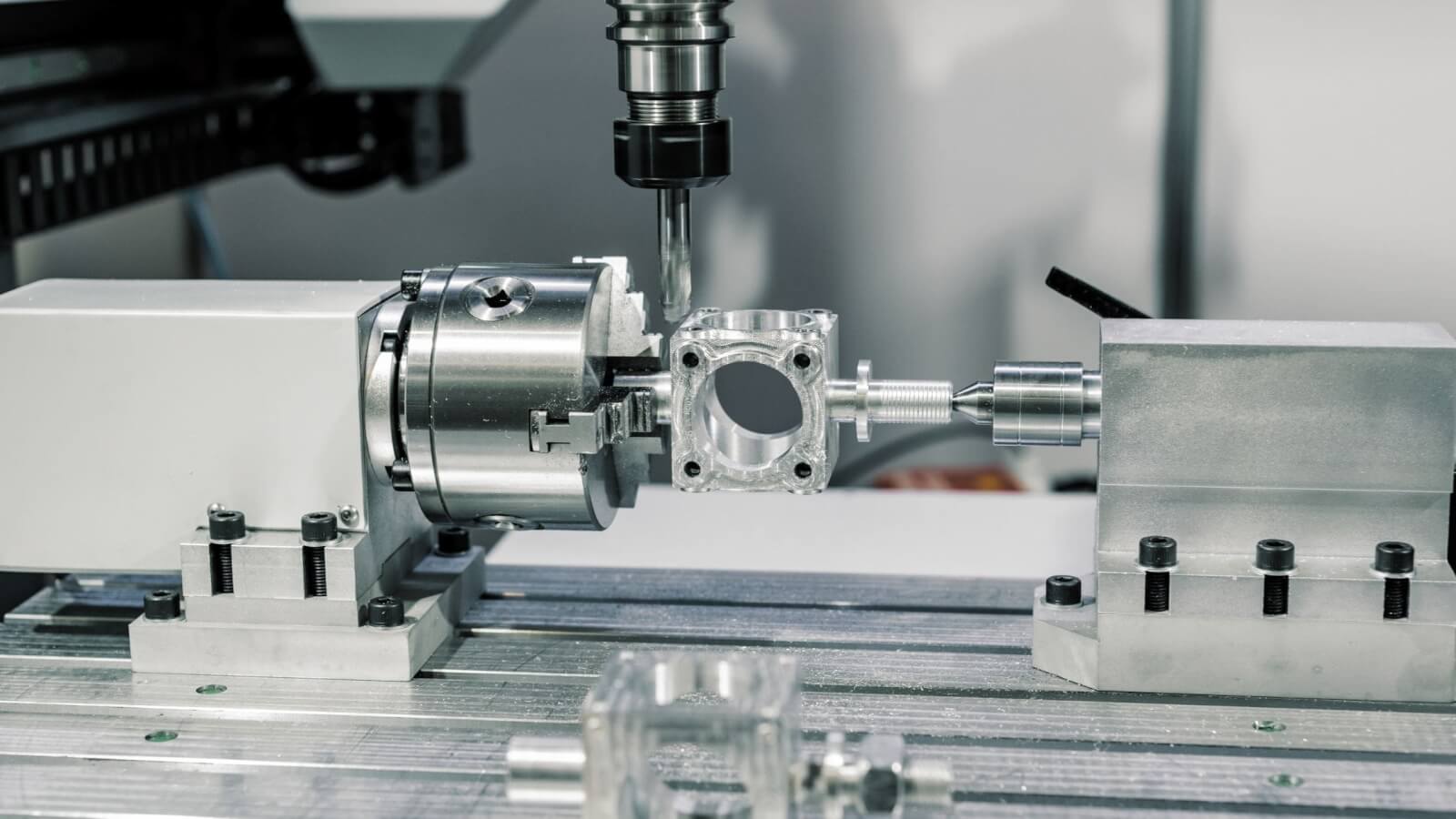

CNC milling has been a game-changer in the industrial industry, providing unmatched precision and adaptability in part and component creation. In addition to its practical uses, cnc milling parts fosters creative creativity by making it possible to realize complicated and one-of-a-kind designs that were previously thought to be impossible. In this piece, we take a tour into the realm of CNC milling and examine the countless opportunities and creative concepts that arise from this revolutionary technology.

- Exceeding Design Boundaries

The advent of CNC milling has broken through conventional design limitations, enabling designers and engineers to push the boundaries of their ingenuity. Because CNC milling can accurately cut elaborate patterns and complex geometry, it may be used to create creative designs that push the envelope and challenge accepted ideas.

2. Sculptural Elegance:

The capacity of CNC milling to turn unprocessed materials into sculptures is among its most remarkable features. With amazing accuracy and detail, CNC milling may be used to create three-dimensional patterns, ranging from flowing organic shapes to meticulously carved sculptures. This skill is used by designers and artists to realize their ideas and create eye-catching, mind-blowing works of art.

- Marvels of Architecture:

CNC milling has completely changed the way that buildings and other structures are planned and built. CNC-milled components provide architectural projects a level of refinement and beauty that is evident in everything from complex façades to unique interior features. Whether it’s geometrically complicated panels or elaborates lattice patterns, CNC milling enables architects to skillfully and precisely implement their architectural ambitions.

- Functional Artistry:

A new kind of practical artwork is created by CNC milling, which blurs the boundaries between art and usefulness. For instance, furniture designers use cnc milling parts to produce custom pieces that perfectly combine form and function. CNC-milled furniture items, which range from elaborately carved tables to sculptural chairs, serve as both useful things and works of art, bringing a touch of refinement and elegance to any environment.

- Automobile Innovation:

The design and manufacture of unique parts and components in the automobile sector heavily relies on CNC milling. Automotive designers may push the limits of design creativity using CNC milling, from complex engine components to custom interior trim pieces. Modern cars are better in terms of performance, looks, and usability when they have CNC-milled parts, whether they be aerodynamic body panels or lightweight structural components.

- Jewelry Making:

The ability to make elaborate patterns with unmatched accuracy and detail has been made possible by CNC milling, which has completely transformed the jewelry-making industry. Jewelers may realize even the most complex designs with CNC milling, from elaborately carved rings to elaborate pendants. Through the utilization of CNC milling, jewelers may produce custom pieces that exhibit their artistic vision and skill.

- Aerospace Advancements:

CNC milling is essential to the design and construction of aircraft components in the aerospace sector, where accuracy and dependability are crucial. In the manufacture of airplanes, CNC-milled parts are widely utilized for anything from engine parts to structural components. Aerospace engineers can create lightweight, highly-strength components with precise tolerances thanks to CNC milling, which improves the efficiency, performance, and safety of contemporary aircraft.

- Innovative Prototyping:

Prototyping has been transformed by CNC milling, which enables engineers and designers to accurately and precisely iterate and perfect their concepts at a rapid pace. Through the direct production of working prototypes from digital designs, CNC milling shortens the time to market and lowers expenses associated with the product development cycle. Designers may realize their ideas with unmatched realism when using CNC-milled prototypes, whether for testing form, fit, and function or assessing design aesthetics.

- Medical Wonders:

CNC milling has revolutionized the design and production of medical equipment and implants in the medical industry. Medical device makers may create accurate, patient-specific solutions using CNC milling, from complex surgical equipment to bespoke orthopedic implants. Healthcare providers may provide individualized treatment and enhance patient outcomes by utilizing CNC milling to create custom medical solutions.

Personalization at Scale

The expanding trend of mass customization is a result of customer demand for individualized products in a number of sectors. This tendency is made possible in large part by CNC milling, which makes it easier to produce specialized parts and components on a large scale. Customized jewelry or smartphone covers may be made to order, and CNC milling enables producers to satisfy the needs of individual customers without sacrificing productivity.

Eco-Friendly Production

CNC milling provides green production solutions in a time when environmental sustainability is critical. CNC machines minimize waste and maximize resource use, which helps to lessen the environmental impact of the sector. Furthermore, the accurate control provided by CNC technology guarantees the effective utilization of resources, hence augmenting sustainability endeavors in production procedures.

Hybrid Composites

The employment of hybrid composites in a variety of applications has been made possible by developments in materials science. These complicated materials may be precisely machined using CNC milling, combining the best features of several components to produce higher performance qualities. Utilizing CNC machining, lightweight, long-lasting components with unmatched structural integrity may be produced using metal matrix composites or carbon fiber reinforced polymers.

Conclusion:

In conclusion, design innovation is fueled by cnc milling parts, which makes it feasible to create complicated and one-of-a-kind designs that were previously unthinkable. CNC milling creates doorways to a world of creative possibilities, from utilitarian artistry to aeronautical developments, from architectural marvels to sculpture masterpieces. We can only speculate about the ground-breaking creations and inventions that lie ahead as technology advances and CNC milling skills increase. The only limits on design in the future are our imaginations when it comes to CNC milling.